In the packaging industry there are several ways to classify machines: by the direction of the process (horizontal or vertical), by the properties of the material used (films, paper-based reels…), by the type of packages created (flowpack, doypack sachets…), or by the function they perform during the packaging process (thermosealing, sealing…).

In this article we will focus on differentiating primary and secondary packaging, two packaging systems that use flow-pack wrappers to make individual packages or groupings (multipacks).

What is primary packaging

Imagine an individual package wrapping a cookie or a blister pack protecting pharmaceutical capsules: it must be functional and attractive at the same time. A flow-pack is designed to meet both requirements, as it allows:

- Hermetically seal packages to prevent the entry of air, moisture or external contaminants.

- Use a variety of films (flexible films) to wrap products.

- Produce accurately at high speed without compromising seal quality or product presentation.

- Customize the package with different types of finishes, either by including an easy-opener or die-cutting, or sealing the package in a zigzag shape, among others.

At Synchropack we are dedicated to primary packaging for food products, especially bakery and confectionery products, as well as pharmaceutical products.

What is secondary packaging

Unlike primary packaging, secondary packaging is focused on logistics and warehousing. Secondary packaging flow-pack wrappers are designed to handle large volumes of products in an organized manner. This type of packaging system groups products together to facilitate their transportation, commercial presentation and protection during the journey to the final points of sale.

An example would be a six-pack of snack bags or a package containing several pharmaceutical blister packs.

Some of the features of flow wrappers for secondary packaging, also known as multipack, are:

- Ability to handle several products at once.

- Integration with automated lines such as robots or feeders that can group and distribute products.

- Compatibility with reinforced films that offer greater resistance during transport.

At Synchropack we also develop secondary wrapping solutions (multipack) for flowpacks, pouches, stickpacks, sachets and blister packs.

Key differences between primary and secondary packaging

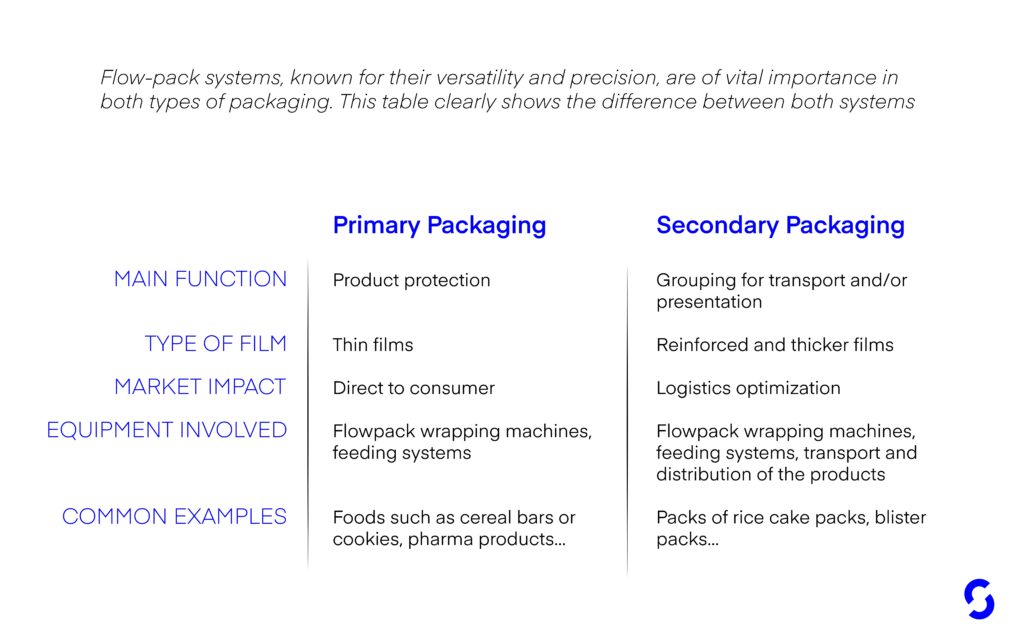

Flow-pack systems, known for their versatility and precision, are of vital importance in both types of packaging. This table clearly shows the differences between the two systems:

If you are looking for packaging solutions that combine accuracy, speed and versatility, our equipment can meet the demands of primary and secondary packaging. Contact us here for more information about our equipment and feeders.