Pharmaceutical packaging plays a key role in the preservation, safety and traceability of medicines and medical devices. In an industry where precision and regulatory compliance are a priority, choosing the right packaging process is a strategic decision that impacts both product protection and consumer trust.

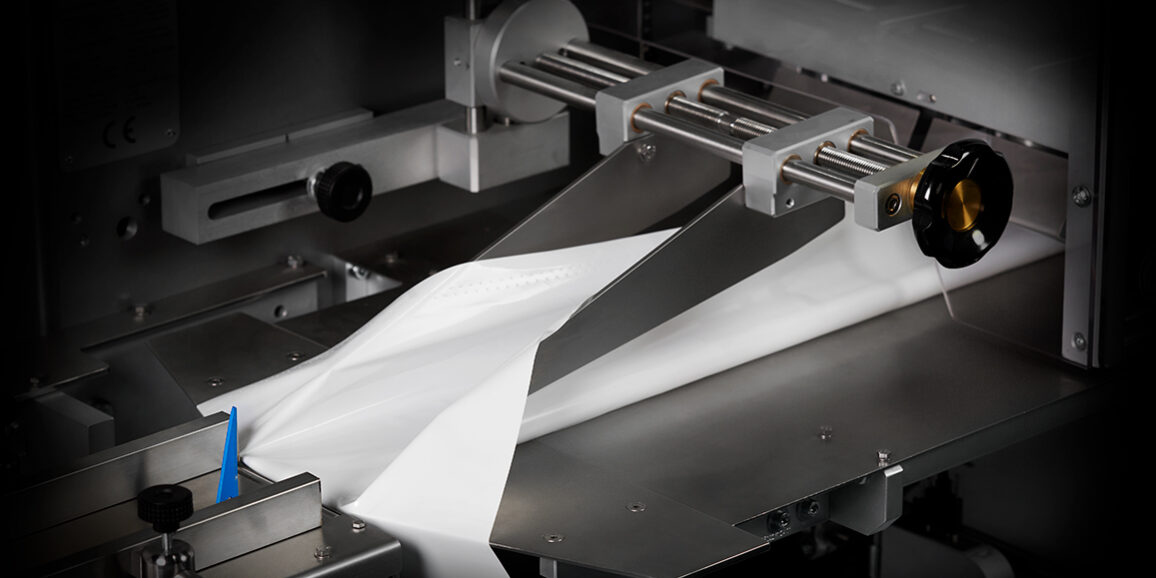

Among the various packaging systems available, the flowpack has gained prominence for its benefits in terms of tightness, efficiency and flexibility.

Why packaging is key in the pharmaceutical industry

Pharmaceutical packaging not only protects the product but also guarantees its stability and efficacy until the time of use. Medicines and medical devices require specific storage conditions to avoid contamination, degradation and alterations in their composition.

In addition to safety, packaging plays an essential role in product traceability. International regulations require that medicines have clear information and coding to facilitate their traceability in the distribution chain. A good flowpack packaging system allows the integration of QR codes, RFID tags or labeling systems, ensuring compliance with regulations and preventing counterfeiting.

On the other hand, packaging also influences the end-user experience. In products such as blister packs, single-dose sachets or tablet strips, ease of opening, accurate dosing and portability are key aspects that influence adherence to treatment.

Another fundamental aspect is the design and material of the packaging. Advances in technology have led to the development of packaging that offers better protection and sustainability. Recyclable and biodegradable materials are gaining ground in the pharmaceutical sector, enabling industry to reduce its environmental impact without compromising product safety.

Benefits of flowpack in pharmaceutical packaging

The flowpack packaging system has proven to be a highly efficient and safe solution for the pharmaceutical industry. Its main benefits include:

- Hermeticity and protection: thanks to its high-quality seal, the flowpack wrapping system provides an effective barrier against moisture, light and contamination, ensuring the stability of the medicine throughout its shelf life. Protection against external agents is crucial for products such as powder formulas, medical devices and sterilized surgical material.

- Efficiency and automation: flowpack packaging machines allow high production speeds, optimizing packaging processes and reducing operating costs. In addition, their integration with serialization systems facilitates compliance with regulatory standards. Pharmaceutical production lines require efficiency and precision, and the flowpack allows errors to be minimized and productivity to be increased without compromising safety.

- Versatility in formats and materials: this type of packaging is ideal for different presentations of pharmaceutical products, from syringes and medical devices to powder sachets or tablets in individual units. Its adaptability allows the use of biodegradable and recyclable materials, aligning with the sustainability trends of the sector.

- Storage and transport optimization: the compact design of the flowpack allows for maximizing space in warehouses and transport. By reducing the size and weight of the packaging, logistics costs are minimized and efficiency in the distribution of pharmaceutical products is improved globally.

- Compliance with regulations and certifications: the pharmaceutical industry is highly regulated, and packaging must meet strict quality standards. Flowpack solutions can be adapted to these requirements, incorporating coding and labeling systems that guarantee regulatory compliance.

Flowpack packaging solutions for the pharmaceutical industry

Pharmaceutical packaging is a crucial element in ensuring the safety, traceability and efficacy of medicines and medical devices. In this context, flowpack packaging is positioned as one of the most advanced and efficient solutions to meet the demanding requirements of the sector.

At Synchropack we offer flowpack packaging machinery specifically designed for the pharmaceutical industry, guaranteeing maximum quality, precision and regulatory compliance. Our state-of-the-art machinery allows for optimized and efficient production.

Contact us through this form and we will work to offer you a customized solution to your business needs.