The flowpack is a very versatile and efficient packaging system that allows products to be wrapped in a flexible film and hermetically sealed. Used in various industries, it extends shelf life and facilitates the transport and distribution of products to the end customer. Its flexibility and adaptability make it an ideal solution for products with high rotation and specific packaging needs. Discover how the flowpack becomes an ally for wrapping seasonal products.

Advantages of flowpack for seasonal products

Seasonal products present logistical and operational challenges for companies due to their fluctuating demand. Flowpack packaging offers multiple advantages for these products, such as:

- Flexibility in production: it allows packaging volumes to be quickly adjusted according to demand.

- Cost optimization: reduces material waste and improves operational efficiency.

- Preservation and protection: the hermetic seal offered by the flowpack protects the product against moisture, contaminants and external damage.

- Packaging customization: allows seasonally specific designs without disrupting the production line.

- Commitment to sustainability: the possibility of using recyclable and biodegradable films minimizes environmental impact.

Which seasonal products can benefit from flowpack?

Flowpack packaging is suitable for a wide range of products for which demand varies according to the season, such as:

Typical festive foods

Consumption of products such as panettone, nougat, Easter chocolates, Christmas cookies or chocolates tend to be very marked by the festive season.

Over-the-counter pharmaceuticals products

They are sold all year round but have some key times where their consumption increases: in the winter flu season, allergy control in spring or skin care in summer.

Frozen products and convenience foods

Frozen products are often convenient and economical options for both restaurants and families, and ready meals are very useful during the return to the office. They often come in savings packs or family packs, such as frozen pizzas or other food products.

School products

Notebook packs, coloring sets and complete school kits are often in demand at back-to-school time for children and teenagers, as they offer convenience to parents and generate a high volume of sales at the start of the school year.

Promotional items

Some companies choose to run promotions at specific times of the year, such as during sales or stock clearance. Changing the individual packaging of products to a multipack version is really useful for companies that want to sell their products at a faster pace.

Benefits of flowpack on the efficiency of the packaging process

The implementation of the flowpack wrapping system in production lines significantly improves the efficiency of the packaging process. The main benefits of flowpack are:

- High production speed.

- Reduction in operating costs.

- Consistency and quality of packaging.

- Synchronization with other machines thanks to automation.

- Adaptability to different sizes and formats without affecting the production rate.

Integration of automatic feeding systems

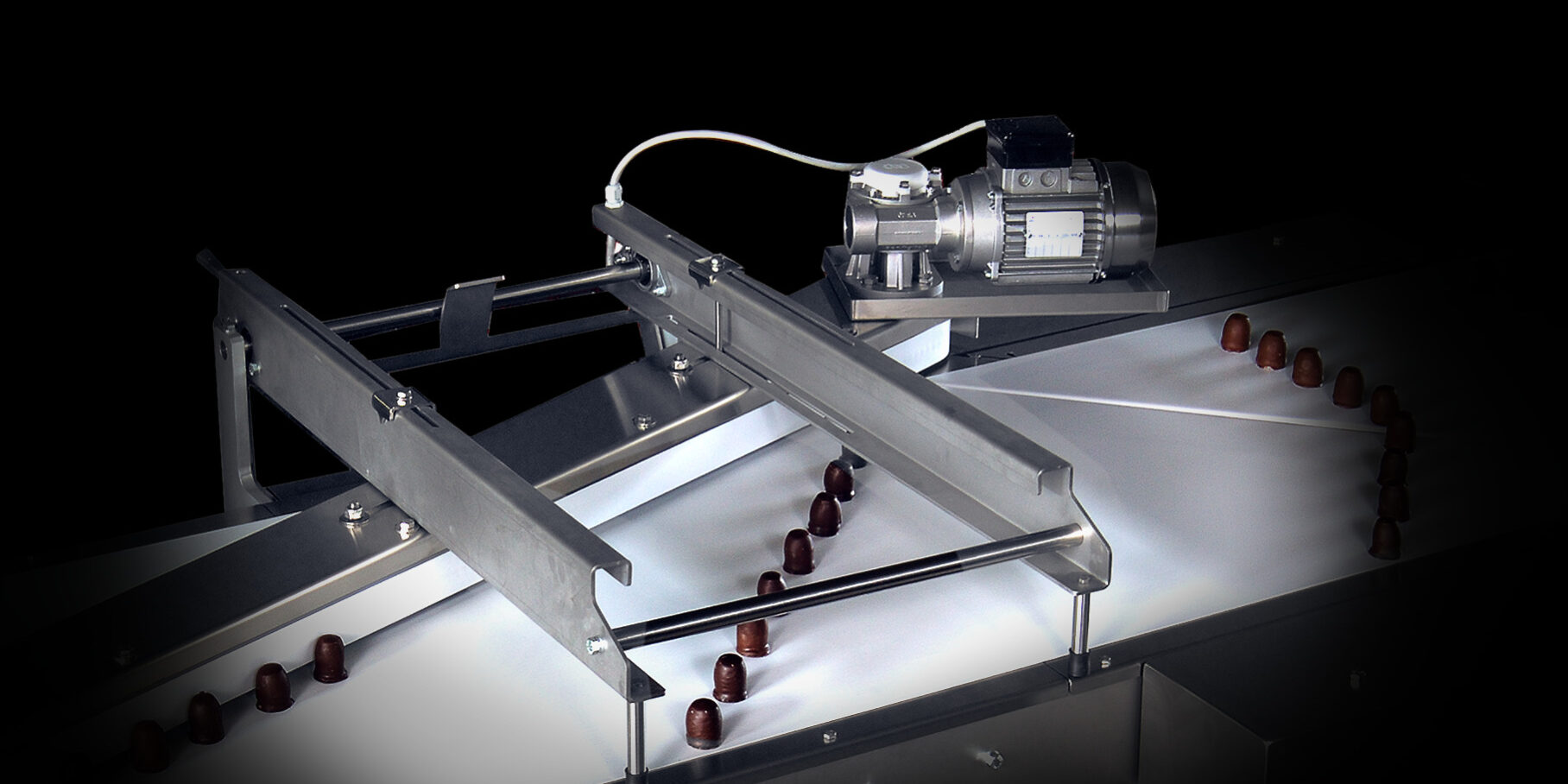

The ability to integrate automatic feeding systems with flow wrappers makes this packaging system a key solution to optimize production.

The automatic feeding systems proposed by Synchropack are:

- Handling and feeding systems. The HFS are specifically developed to create portions of products, either in flat stack format, portions in upright or edgewise position or groupings of grissines.

- Conveyor Feeding Systems. The CFS are responsible for sorting, handling, orienting and distributing different products synchronously to the flow-wrappers.

- Robot Feeding Systems. The different robots that make up the RFS group are used for single or multiple picking of light or heavy products at various production speeds.

Automation in the feeding process reduces dependence on human intervention, which translates into greater efficiency, less margin for error and more sustainable production.

The flowpack as an ally for efficiency

The flowpack is a highly adaptable solution for the packaging of seasonal products, as it allows flexibility in production, cost optimization and customization of packaging according to the season. In addition, its integration with automatic feeding systems maximizes process efficiency, reducing the need for manual intervention and ensuring greater speed and accuracy in packaging.

For companies looking to improve their responsiveness to seasonal demand, investing in flowpack machinery with automatic feeding is a key strategy to ensure competitiveness, efficiency and sustainability in their production.