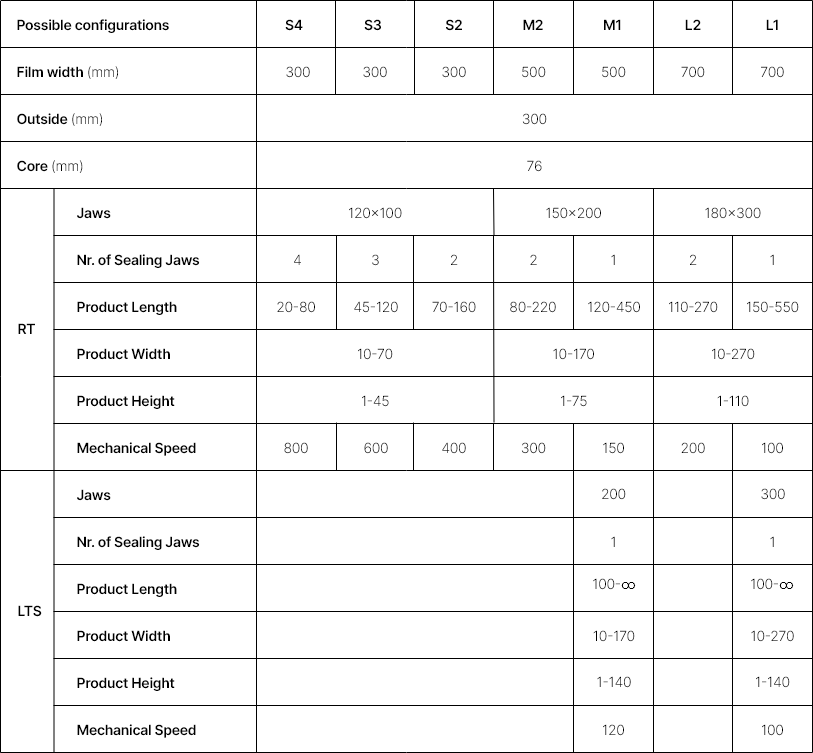

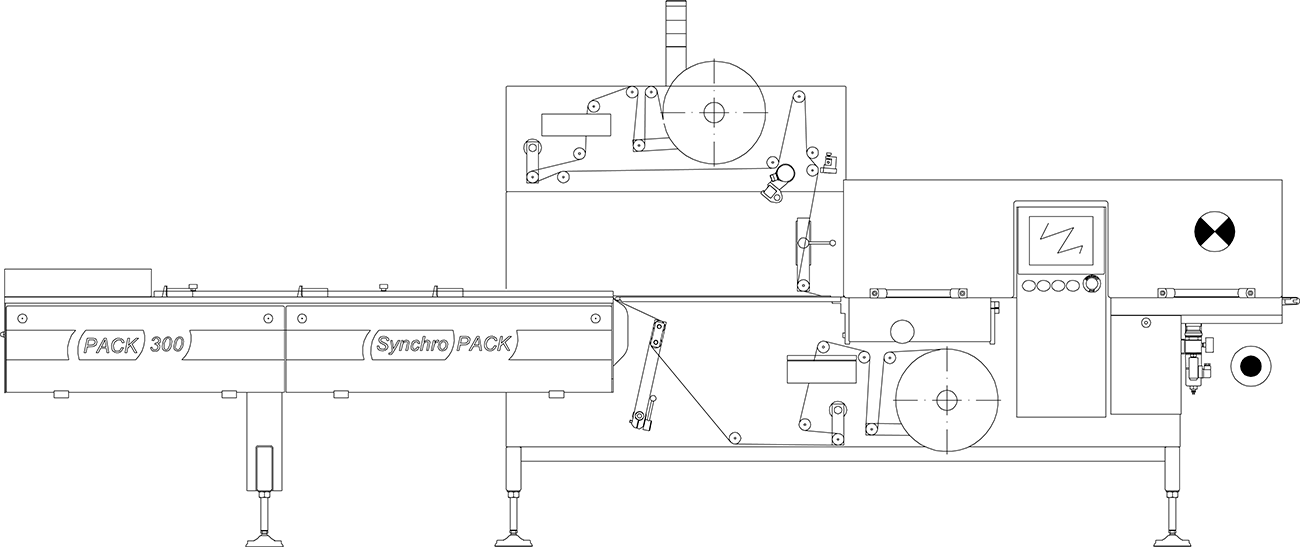

Conveyor belt with easily removable pusher paddles to vary the distance between them, without the need of tools.

Pack 300

for medium production runs

Cantilever design, Modular construction, High flexibility & Performance, Ease of operation & Changeover, Low maintenance cost and full electronic control, are the main features of this model of wrapping machine.

This common platform has been used to develop multiple configurations that combined with a wide range of available accessories allow the Pack 300 to be adapted to many different products as well as to the most demanding requirements in all kind of production environments.

Our large experience also enables us to offer a wide number of accessories and feeding systems for the greatest variety of different products.

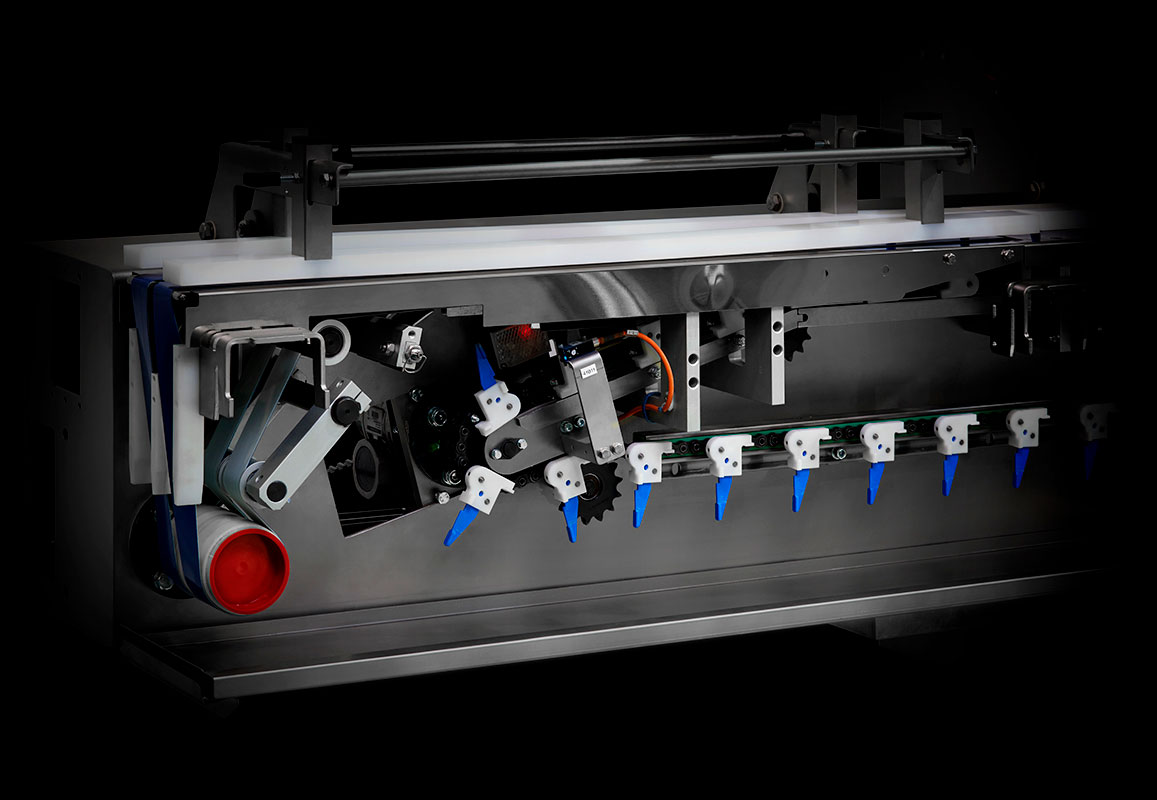

Pallet conveyor

Reel holder

Pneumatically expanding upper reel holder shaft, for a firm hold of the film reels. It provides axial adjustment on the operator’s side, which can be operated while the machine is running.

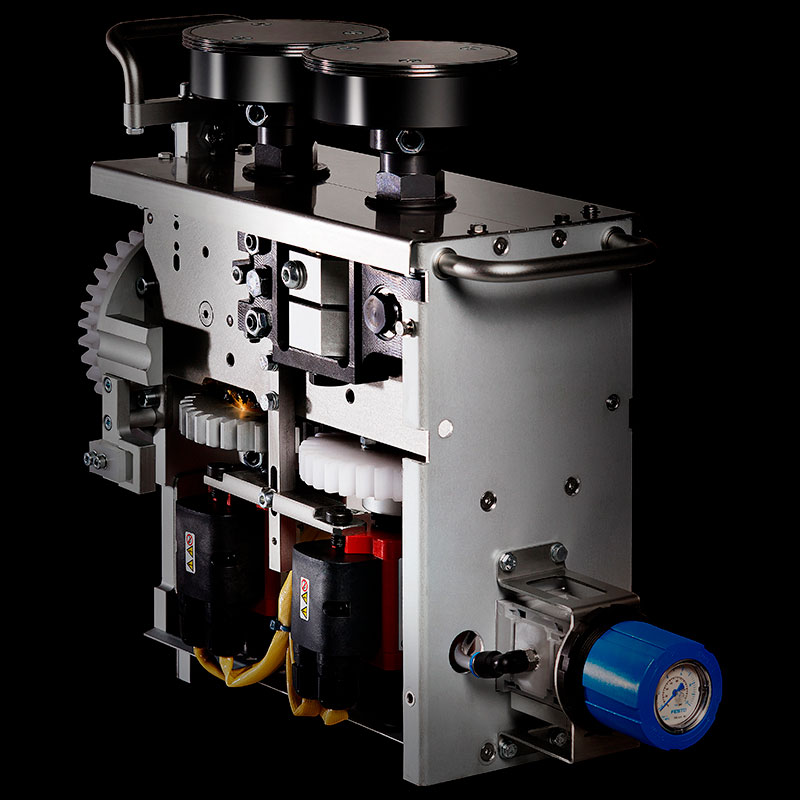

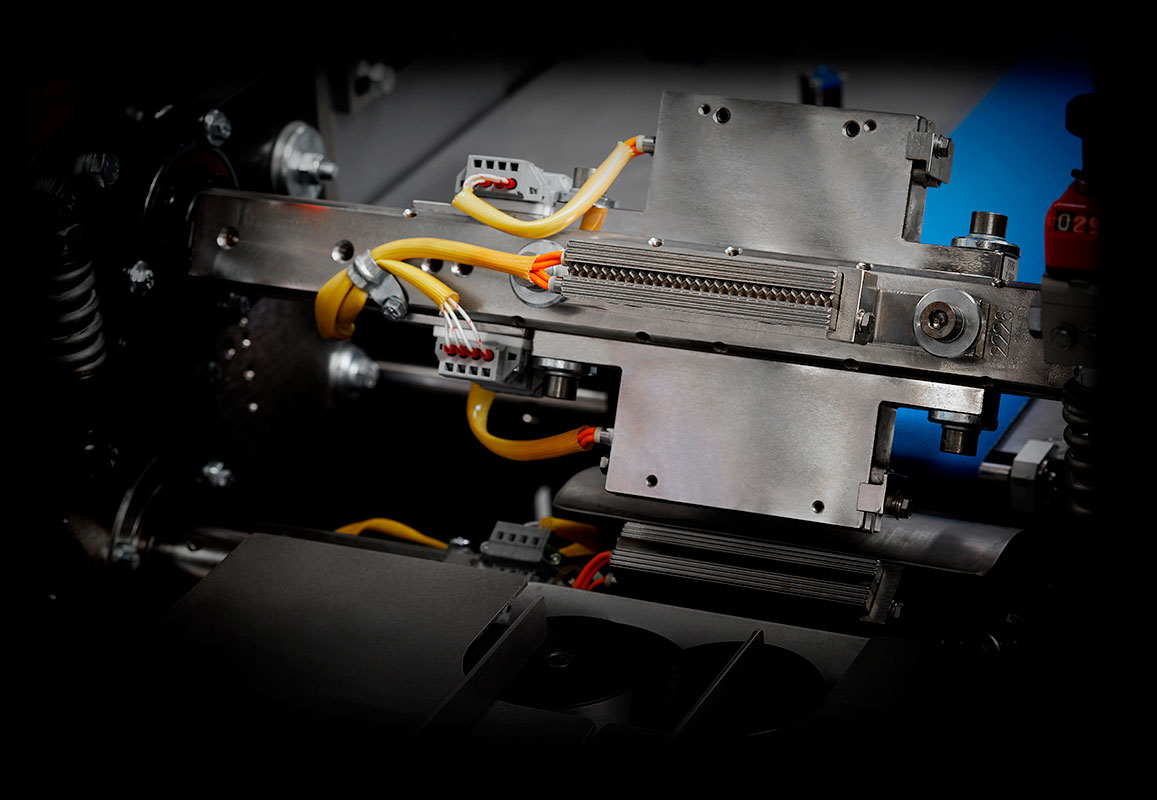

Longitudinal sealing unit

Longitudinal sealing unit of modular type, composed of a pair of cold wheels for film dragging, 2 pairs of heated wheels for sealing and a pair of conical wheels for bending the longitudinal sealing flange.

Longitudinal welding module

Longitudinal welding module easily removable, simply needing to loosen 2 screws and an electric-pneumatic connector, for maintenance/cleaning operations, with the possibility of quick replacement with a spare module.

Longitudinal sealing unit

Longitudinal sealing unit of modular type, composed of a pair of cold wheels for film dragging, 2 pairs of heated wheels for sealing and a pair of conical wheels for bending the longitudinal sealing flange.

Outfeed conveyor with ejection

Outfeed conveyor for the already wrapped product equipped with independent variable speed motorization, adjustable according to the wrapping speed, with detection and rejection system for empty and double bags.

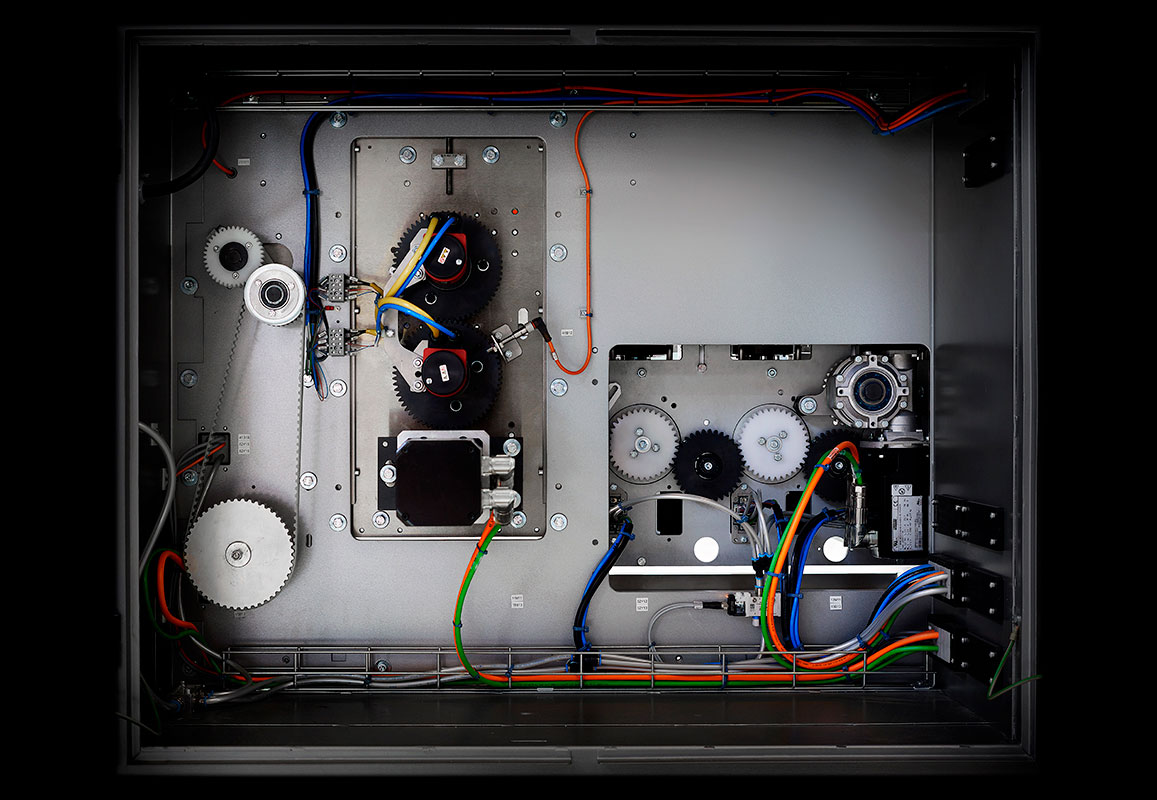

Transmission

Transmission cabinet.

Touch screen display

10.4″ color touch screen for intuitive operator-machine interaction, with the possibility of displaying all operating parameters, warnings, alarms, etc.

| Safety Compilance | CE Directive 98/37/CE CE Directive 89/336 CEE - 93/68/CEE CE Directive 72/23 CEE - 93/68/CEE EN 415-3 / EN 60204-1 / EN ISO 12100-1 / EN ISO 12100-2 / EN 294 / EN 418 |

| Power Supply | 380-440 VAC / 3 Ph / 50-60 HZ |

| Electrical Consumption | From 6 to 15 kw Depending on machine configuration |

| Air Consumption | From 0 to 50 L / min @ 6 bar |

| Noise Level | Less than 80 db |

| Weight | Between 1000 - 1500 kg |

| Colour | RAL 9007 Silver Metallic Grey |

| Thermo | for heatsealable films |

| Cold | for cold sealing films |

| RT | Rotary type sealer / cutter |

| Inox | Stainless Steel execution |

| RH | “Right hand” execution |