Packaging plays a fundamental role in the confectionery industry, where product presentation, protection and extended shelf life are key aspects. Among the different packaging technologies available, the flowpack system has established itself as a versatile and efficient solution.

Its ability to wrap products of various shapes and sizes, together with its airtightness and visual appeal, make it an ideal option for confectionery manufacturers seeking to optimize their processes and guarantee the quality of their products.

Challenges and needs in the confectionery industry

Confectionery manufacturers face a range of challenges from product protection to production optimization and packaging sustainability. Some of the main challenges include:

Preserving freshness and quality

Products such as chocolates, candies and sweets must be kept in optimal conditions to avoid alterations in their flavor, texture or appearance. The flowpack packaging system helps to maintain the organoleptic characteristics of the food.

Efficiency in the packaging process

High product demand requires fast and flexible production lines that reduce waste and improve productivity. Confectionery is a daily consumption industry, so packaging efficiency must be a top priority.

Attractive presentation

Eye-catching and functional packaging is key to stand out at the point of sale. The flowpack packaging system allows different film reels to be used on the same machine, so seasonal (e.g. during festive campaigns or discount periods) and eye-catching products can be wrapped easily and quickly.

Sustainability and reduction of plastics

The industry is looking for more environmentally friendly packaging alternatives without compromising product protection. At Synchropack we work to adapt them to our customers’ needs, and the R&D team develops and evolves the right technology and machinery for the use of sustainable wrapping materials.

Advantages of flowpack packaging for food products

Flowpack packaging effectively meets these challenges thanks to its numerous advantages, which can be summarized in three key points:

- Maximum product protection. The flowpack wrapping offers an airtight seal that protects against moisture, light and oxygen, prolonging the shelf life of products and ensuring freshness.

- Efficiency and versatility. It allows a wide variety of products to be packaged at high speed, adapting to different formats and materials, from traditional plastic films to biodegradable or mono-material

- Optimized presentation and sustainability. Facilitates customization with high quality printed designs and minimizes the use of packaging material, reducing costs and environmental impact.

Flowpack applications in the confectionery industry

The flowpack system is widely used in the confectionery industry for the packaging of various products:

Chocolate bars

Chocolate bars require packaging that preserves their texture and flavor, avoiding exposure to moisture and air. The flowpack wrapping provides an effective barrier against external agents and allows an attractive design with easy opening, enhancing the consumer experience. In addition, automatic feeding systems can be integrated to load the product directly into the flow-wrapper, avoiding the possibility of cross-contamination. The integration of these feeders also maximizes operational efficiency.

Cereal bars

Cereal and energy bars need packaging that ensures freshness and avoids moisture absorption, which could affect their crunchiness. Flowpack packaging offers hermetic sealing and the possibility of incorporating oxygen barrier materials for added protection. In addition, easy-open systems and multipack formats can be applied to meet various market needs.

Confectionery

Confectionery, such as candies and chewing gum, can be packaged individually or in portion-controlled bags by flowpack. This type of packaging ensures that the products retain their shape and flavor. The versatility of the flowpack allows the integration of modified atmosphere packaging systems for moisture-sensitive products.

Licorice

The flowpack packaging of licorice allows it to maintain its texture and avoid premature hardening. The possibility of using printed films helps to improve product presentation, which is key in a highly competitive market. In addition, the flowpack facilitates the creation of resealable packages, ideal for progressive consumption products.

Pastry

In industrial bakery, flowpack is used for products such as cookies, muffins and croissants. Its airtightness prevents loss of freshness and maintains the original texture. It also allows the application of technologies such as modified atmosphere packaging, which extends the shelf life of products sensitive to oxidation and softening.

Case studies: complete packaging lines

Synchropack has developed complete packaging projects for different products in the confectionery sector. One of the success stories that we have developed is a complete line for the

Primary packaging case study

At Synchropack we developed a complete line for the individual wrapping of chocolate bars at 500ppm. The line is composed of a range distribution system (RDS) with double exit, two product rotation systems (RPS), two high speed synchronizers (HSS) and two Pack 900 RT wrappers.

Secondary packaging case study

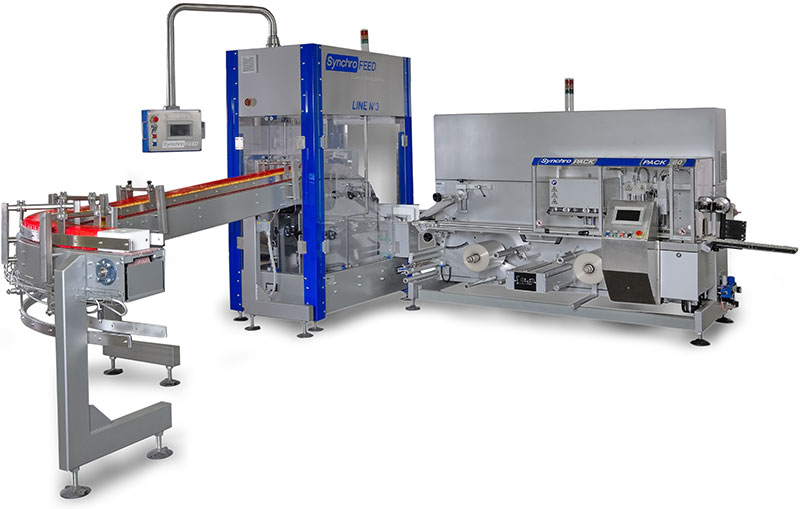

We also designed and assembled a complete line for wrapping chocolate bars in stacks of 2 to 10 units. The line is composed of a pile automatic feeder (PAF) and a Pack 60 LTS wrapper.

Flowpack packaging has become an indispensable solution for the confectionery industry thanks to its ability to guarantee freshness, optimize production and enhance the consumer experience. Its flexibility, efficiency and adaptability to different products make it the best option for manufacturers seeking innovation and quality in their packaging processes.