In a world where efficiency and precision are key, flow pack wrappers have become indispensable tools in the packaging industry. But how exactly do these machines work? In this article, we will explore how flow pack wrappers work and how they can improve business efficiency. And there is no better source for this than Synchropack, an international reference in the packaging world as manufacturers of packaging machinery and custom-made automatic solutions.

What are and how do flow pack wrappers work?

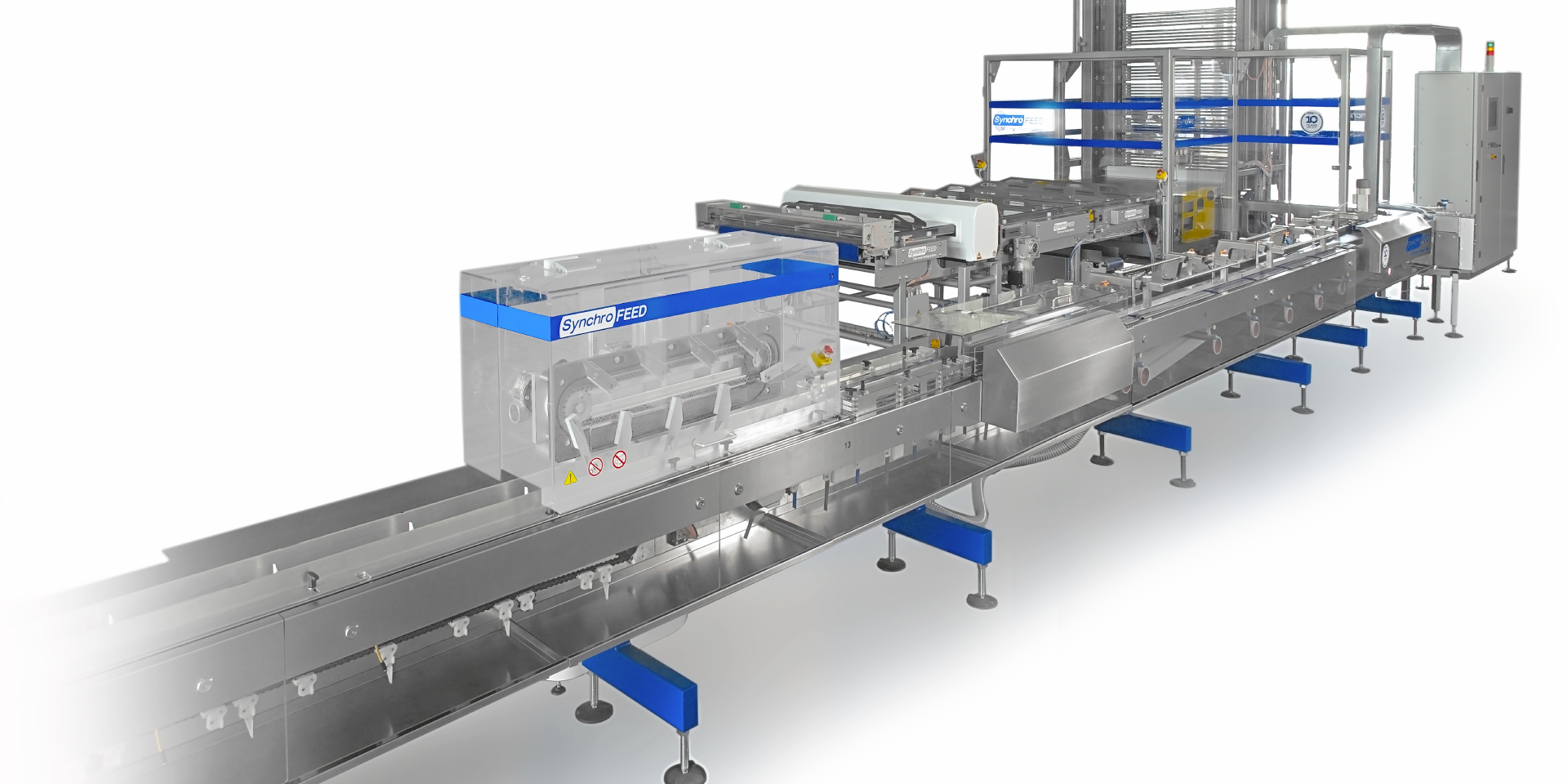

Flow pack wrappers are specialized machines that use a horizontal packaging technique to seal and protect products. They use a plastic film that is sealed around the product, forming an airtight and secure package. This packaging technology is essential in a variety of industries, including food, pharmaceutical and cosmetics.

Key components of a flowpack wrapper

Film reel

The film reel is the material used to wrap the product. It can be made of different materials, such as plastic, aluminum or paper, depending on the needs of the product.

Sealing System

The sealing system is the heart of the flowpack wrapper. It uses heat to seal the film around the product, ensuring a hermetic and secure seal.

Cutting System

Once sealed, the cutting system separates the pack individually. This is done accurately and efficiently, ensuring a clean and uniform cut.

Flowpack Packaging Process

- Product Infeed: Products are placed on a conveyor belt that guides them into the machine.

- Film Forming: The film reel is unwound and formed around the product.

- Sealing: Heat is applied to seal the film, creating an airtight package.

- Cutting: The cutting system separates each package individually.

- Output: Finished packages are sent to the next stage of the production chain, either warehousing or distribution.

Benefits of Using Synchropack Flowpack Wrappers

Synchropack offers not only high quality packaging machines, but also customized automatic tailor-made solutions. Some of the benefits of using our flow wrappers include:

Improved Efficiency

With our machines, you can increase production speed and minimize waste, leading to higher throughput and cost savings.

Flexibility

Our flow pack wrappers can adapt to a wide variety of products and sizes, offering a truly customized packaging solution.

Sustainability

At Synchropack, we are committed to sustainability. We offer eco-friendly packaging options and work to reduce the environmental impact of our machines.

Types of Flowpack Wrapping Machines at Synchropack

At Synchropack, we understand that every business has unique needs. That’s why we offer several types of flow pack wrappers to suit different requirements and applications:

1. High Speed Wrappers

These machines are designed to handle large production volumes, offering exceptional speed and efficiency.

2. Flexible and Modular Wrappers

For those who need a versatile solution, our modular wrappers can be configured to handle a variety of product sizes and shapes.

3. Specialty Wrappers

For products that require a unique approach, we offer specialized stretch wrappers designed specifically for certain types of products, such as fresh food or medical devices.

4. Eco-Friendly Wrappers

Committed to sustainability, our eco-friendly wrappers use recyclable materials and processes that reduce waste and energy consumption.

Conclusion

Flow wrappers are a revolutionary technology in the packaging world. Synchropack, as a leading manufacturer of these machines, offers solutions that not only meet but exceed expectations. If you are looking to improve efficiency and accuracy in your packaging process, look no further, Synchropack has the perfect solution for you. Contact us and find out what we can do for your business!